Economy

09 August 2022

US imports are expected to slow in the second half of 2022

NRF projects a comedown from record highs. Supply chain challenges are "far from over."

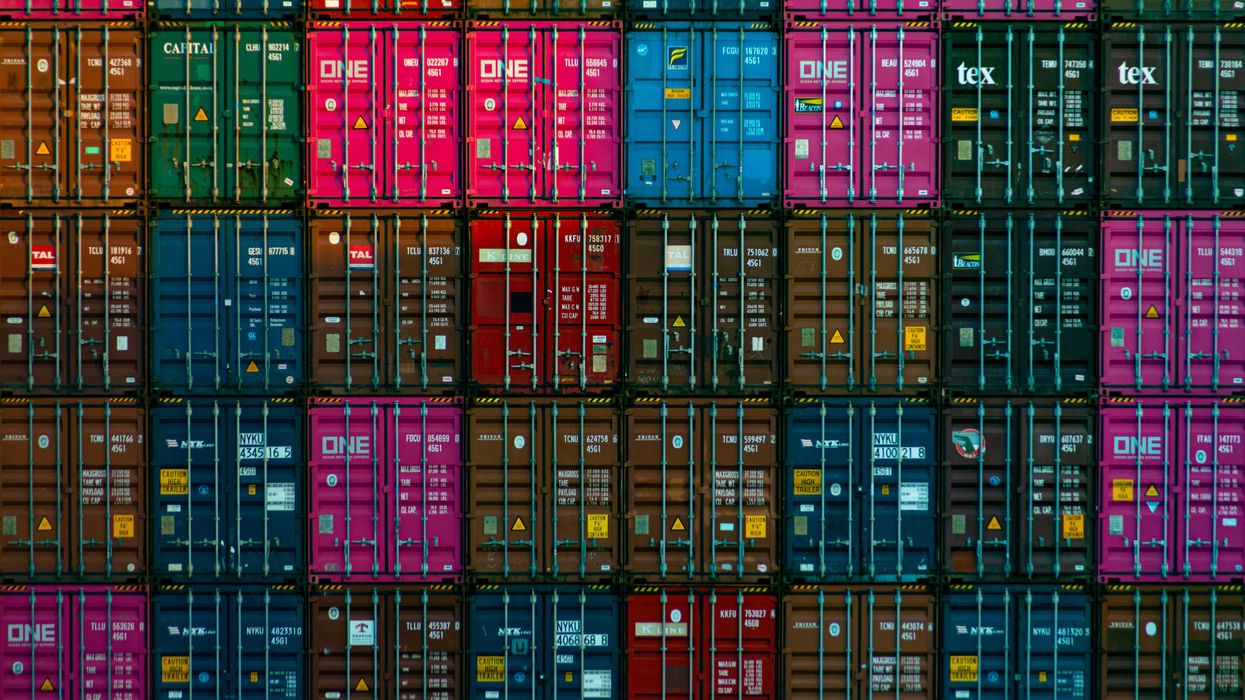

Port activity is easing up. (Photo by Teng Yuhong on Unsplash)

NRF projects a comedown from record highs. Supply chain challenges are "far from over."

American ports are expected to see a slowdown in imports for the second half of 2022, reflecting an economy that is seeing waning productivity and interest rate hikes from the Federal Reserve.

The Global Port Tracker from the National Retail Federation (NRF) and Hackett Associates projects that the second half of the year will bring in 12.8 million Twenty Foot Equivalents (TEUs), a measure that reflects a 20-foot container or its equivalent. That would be a year-over-year decrease of 1.5% for the second half period.

“Retail sales are still growing, but the economy is slowing down and that is reflected in cargo imports,” NRF Vice President for Supply Chain and Customs Policy Jonathan Gold said.

The slowing second half would follow an all-time-high volume of cargo handling in the first half of the year. The first six months saw a year-over-year increase of 5.5%, with 13.5 million TEUs brought in. For the year, the report is projecting 26.3 million TEUs, which would be a 2% increase over 2021’s record of 25.8 million TEUs.

In June, which is the latest month for which numbers are available, the ports tracked by NRF handled 2.25 million TEUs, which was a 4.9% year-over-year increase. But that was down from May, which saw 2.4 million TEUs – a monthly record for the report since it began in 2002. That came as easing supply chain snarls led to a glut of inventory at retailers that is now being moved through markdowns. The chaos can still be observed, as the nation's largest warehouse in California is reportedly running out of space amid slowdowns in spending on home goods, electronics and other categories that were popular amid lockdowns.

The projections for the next six months at the ports offers signs that balance is being restored.

“The heady days of growth in imports are quickly receding,” Hackett Associates Founder Ben Hackett said. “The outlook is for a decline in volumes compared with 2021 over the next few months, and the decline is expected to deepen in 2023.”

The expected reduced activity in the second half of the year comes as supply chain challenges continue to be an issue for brands and retailers, even as taming 40-year-high inflation has become the primary focus of economic leaders. The continued war in Ukraine and labor shortages are continuing to cause disruptions in the systems that move goods.

“Lower volumes may help ease congestion at some ports, but others are still seeing backups and global supply chain challenges are far from over,” Gold said.

Labor-related disputes also have the potential to roil ports, and the American supply chain. A few updates from the last month offer examples:

The stakes of potential disruption for retailers only grows as retail momentum builds toward the end-of-year holidays, and remains the NRF’s “biggest concern.”

“Concluding both sets of negotiations without disruption is critical as the important holiday season approaches,” Gold said.

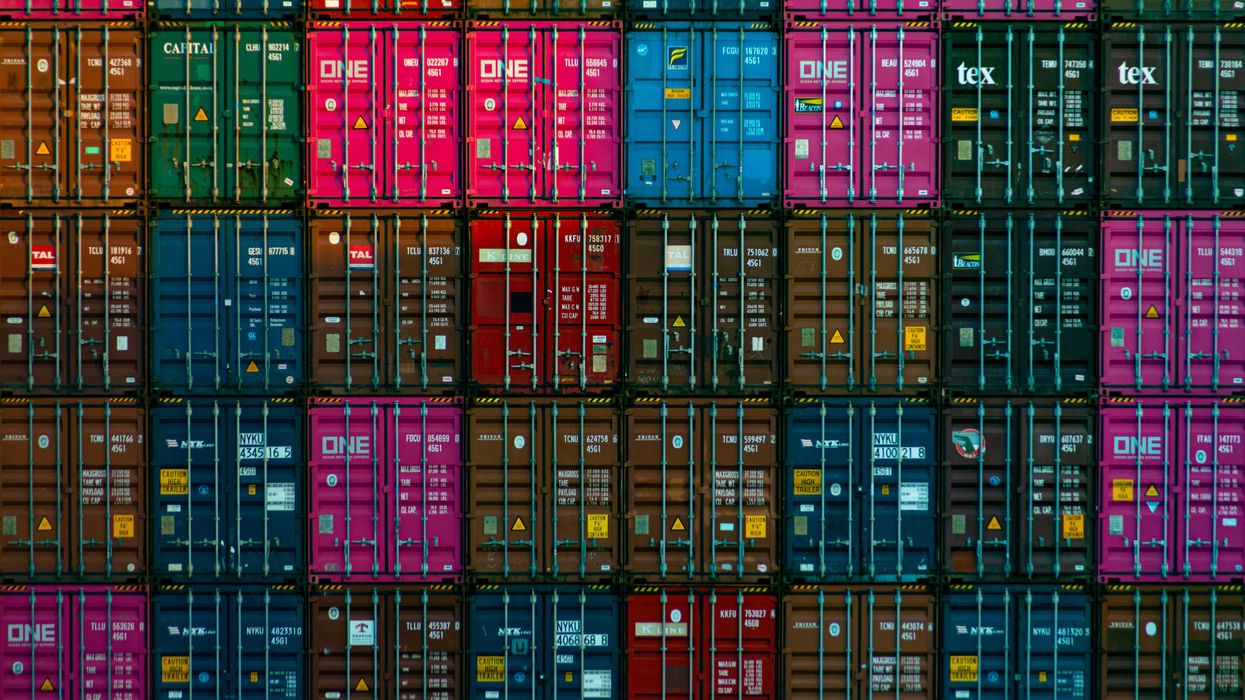

Labor disputes on the West Coast could cause further disruption heading into peak season.

When the first half of 2023 is complete, imports are expected to dip 22% below last year.

That’s according to new data from the Global Port Tracker, which is compiled monthly by the National Retail Federation and Hackett Associates.

The decline has been building over the entire year, as imports dipped in the winter. With the spring, volume started to rebound. In April, the major ports handled 1.78 million Twenty-Foot Equivalent Units. That was an increase of 9.6% from March. Still it was a decline of 21.3% year over year – reflecting the record cargo hauled in over the spike in consumer demand of 2021 and the inventory glut 2022.

In 2023, consumer spending is remaining resilient with in a strong job market, despite the collision of inflation and interest rates. The economy remains different from pre-pandemic days, but shipping volumes are beginning to once again resemble the time before COVID-19.

“Economists and shipping lines increasingly wonder why the decline in container import demand is so much at odds with continuous growth in consumer demand,” said Hackett Associates Founder Ben Hackett, in a statement. “Import container shipments have returned the pre-pandemic levels seen in 2019 and appear likely to stay there for a while.”

Retailers and logistics professionals alike are looking to the second half of the year for a potential upswing. Peak shipping season occurs in the summer, which is in preparation for peak shopping season over the holidays.

Yet disruption could occur on the West Coast if labor issues can’t be settled. This week, ports from Los Angeles to Seattle reported closures and slowdowns as ongoing union disputes boil over, CNBC reported. NRF called on the Biden administration to intervene.

“Cargo volume is lower than last year but retailers are entering the busiest shipping season of the year bringing in holiday merchandise. The last thing retailers and other shippers need is ongoing disruption at the ports,” aid NRF Vice President for Supply Chain and Customs Policy Jonathan Gold said. “If labor and management can’t reach agreement and operate smoothly and efficiently, retailers will have no choice but to continue to take their cargo to East Coast and Gulf Coast gateways. We continue to urge the administration to step in and help the parties reach an agreement and end the disruptions so operations can return to normal. We’ve had enough unavoidable supply chain issues the past two years. This is not the time for one that can be avoided.”