A 3D version of a product doesn’t have to appear in one place.

With 10 years of experience in ecommerce, that’s a hard-won lesson for Emersya, a 3D and AR product experience platform that helps brands bring digital versions of physical goods to life.

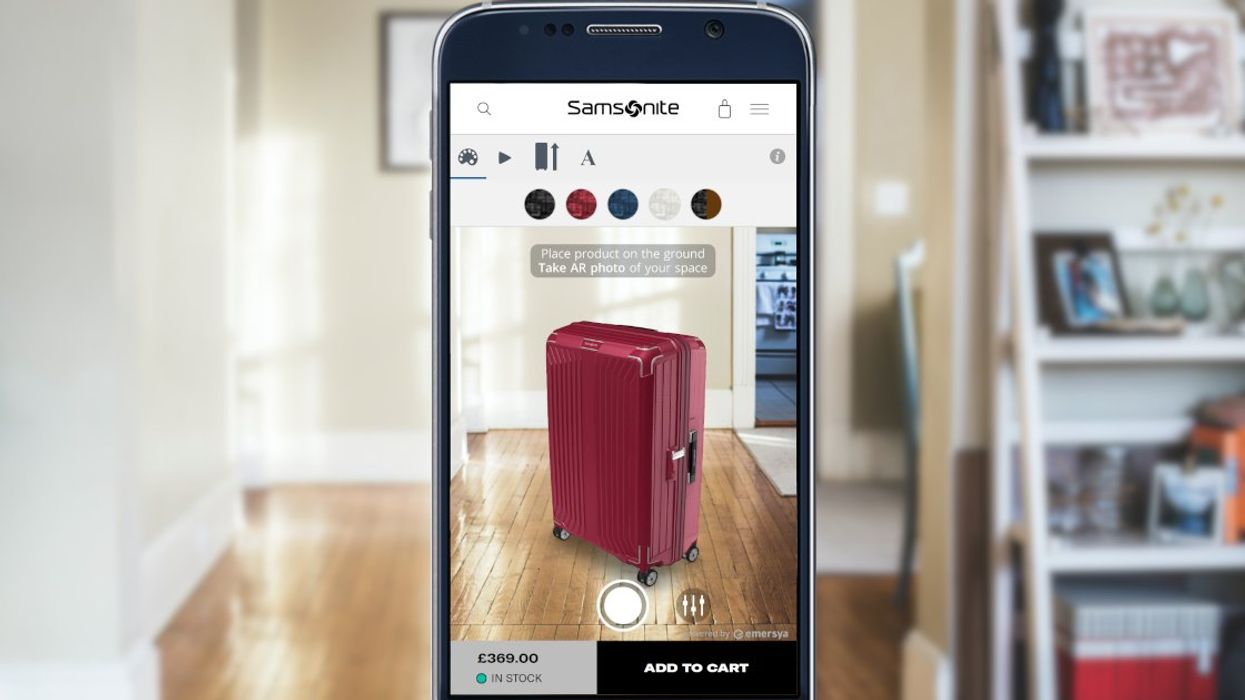

On the floor of the NRF Big Show 2023, Emersya demonstrated its work with Samsonite to create a more interactive online shopping experience.

On a mobile device or tablet, a shopper can scroll around a suitcase to view it from all sides. Then, additional animations open the suitcase, and allow the shopper to see what it looks like inside.

It’s also possible to visualize the suitcase in augmented reality. From directly within the product page – no app required – a user could visualize the suitcase at scale in their physical surroundings, using their device’s camera.

“For Samsonite, that was really important, because they have different size suitcases,” said Emma Freeman, international partnerships and communications manager at Emersya. “So seeing the suitcase, and being able to switch between the different sizes, in real time, in AR, was a real added value for their customers.”

As new capabilities are introduced, use cases can be applied across categories. With augmented reality, Emersya in 2021 rolled out a virtual try-on feature that allows shoppers to see what headwear accessories like glasses would look like on their person in real-time.

Emersya’s trajectory demonstrates how 3D asset use is moving into wider adoption. But that’s not only because the technology is advancing, and cloud-based, API-driven software is making deployment easier. The use gets at a key tension point in ecommerce: Shoppers enjoy the convenience of being able to browse and buy from anywhere they are. But they can’t actually touch, feel and explore the product like they would in a store. 3D images provide a way to dive deeper into the products.

This has real implications for the bottom line of brands and retailers. If a consumer doesn’t have a good line of sight and grasp of what they are buying, they are more likely to return it.

Emersya also sees how digital assets can augment the store experience. More clients are using 3D models on tablets and other devices to to provide technical details through exploded views or product personalization experiences.

This omnichannel approach hints at how commerce is converging across physical and digital touchpoints. A brand must show up at each. If the experiences are similar, it will allow them to delight customers anywhere they may be traveling.

3D technology can serve brands before a product reaches the consumer, as well. Emersya has developed an online 3D solution that enables brands to leverage digital twins during the product design process. The solution allows designers to create product collections in 3D to reduce the number of physical samples manufactured, and to speed up the time to market.

3D assets are moving beyond the experimentation phase. Brands have a growing number of uses, appearing across many touchpoints. Emersya designed its software to allow for centralized creation and management as this activity expands.

That's how the value of a single 3D asset grows.

“Rather than investing in different solutions for each touchpoint, you can have one solution that adapts,” Freeman said.